VISIT US at MINExpo

Booth # 11138

MELTRIC is Ideal for Mining Applications

Stay Connected at All Times

MELTRIC plugs and receptacles offer unmatched plug-and-play connectivity for your electrical power needs. When you choose MELTRIC, you choose are choosing improved savings, time management, and safety.

Try a Device, On Us

MELTRIC SWITCH-RATED PLUGS AND RECEPTACLES...

are the ideal solution for power distribution, conveyor connections, pump power supplies, motor control connections, process equipment connections, high hp motor connections, power supply to heavy-duty machinery, and control wire connections for the mining, aggregate and concrete industries.

Safe & Reliable Uptime

Reduce Power-Related Failures with MELTRIC Plug-and-Play Devices

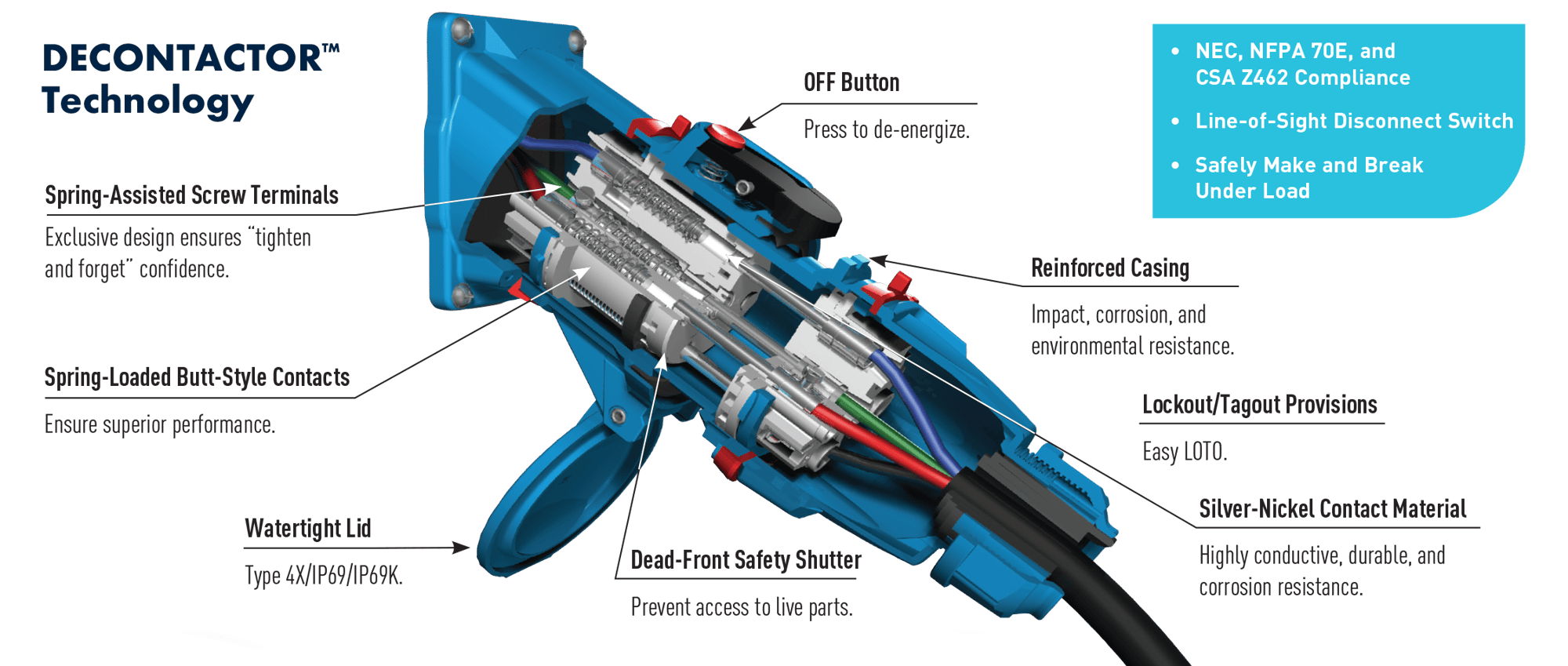

MELTRIC helps optimize power distribution and minimize electrical downtime, contributing to overall energy efficiency in your operations. With a unique dead-front safety shutter and mechanical keying, workers are protected and connections are made easy.

MELTRIC devices ensure that your mining and aggregate equipment has reliable and durable connections that allow you to make changes, at a moments notice, to avoid downtime and other electrical related disruptions.

The MELTRIC Advantage

The MELTRIC® Advantage means exclusive Switch-Rated safety that you can rely on and trust. MELTRIC Switch-Rated Plugs and receptacles combine two distinct safety elements in one design. A dead-front safety shutter isolates all live parts, removing the risk of electrical shock to operators. Additionally, an arc-flash chamber safeguards users, allowing them to safely disconnect, even when under load. MELTRIC design helps ensure worker safety while reducing equipment and labor costs.

Most MELTRIC products are UL/CSA rated for motor circuit disconnect switching, and meet NEC code requirements for line-of-sight disconnects. Our devices also include lockout/tagout (LOTO) provisions, are watertight, and simplify NFPA 70E normal operation code compliance. Switch-Rated plugs and receptacles eliminate the need for expensive auxiliary disconnects and enable plug and play equipment changeouts.

Watertight Operation

Good sanitation is critical in the food and beverage industry, but frequent washdowns with caustic cleaners can be brutal on equipment. Make clean-up and maintenance safer and more efficient with MELTRIC Switch-Rated devices. They are watertight and built to withstand the rigors of food and beverage processing and washdowns.

DSN Series devices are designed to automatically ensure up to Type 4X/IP69/IP69K rated watertightness as soon as the plug and receptacle are mated, or when the receptacle lid is closed. There is no need to thread on or engage sealing rings as on many pin and sleeve devices.*

Additionally, MELTRIC builds in durable:

• Stainless steel hardware that withstands corrosion

• Silver-nickel contacts that provide reliable conductivity in harsh environments

• Chemical-resistant casings

*DS Series devices must be ordered as Type 4X for watertight protection.

Chemical-Resistant Casings

MELTRIC chemical-resistant poly casings can withstand commercial-strength cleaning products, including the top five most common solutions:

• Chlorinated cleaners (Chlorine Dioxide)

• Sanitizers and disinfectants (Hypochlorites)

• Foaming cleaners (Iodophors)

• Ammonium

• Heavy- acid cleaners (CIP Acid)

Consult the MELTRIC Catalog for a detailed list of chemical agents and casing resistance.

MELTRIC Simplifies NFPA 70E Compliance

MELTRIC Switch-Rated plugs and receptacles simplify compliance with NFPA 70E by eliminating exposure to live parts and arcing when making and breaking electrical connections to changeout or service motors and other equipment. The hazard is eliminated, so there is no need for cumbersome PPE or time-consuming safety procedures.

MELTRIC Switch-Rated plugs and receptacles are designed specifically to ensure safe use and are UL/CSA rated for branch circuit and motor circuit disconnect switching.

-

They have a quick break mechanism that automatically ejects the plug to the ‘Off’ position and minimizes associated arcing.

-

Arcing that does occur is safely contained and isolated in internal arc chambers.

-

The design of the casings prevents access to live parts when the plug is ejected to the ‘Off’ position; this dead-front is maintained by a safety shutter which closes automatically over the receptacle contacts before the plug can be removed.

At no time in the process is the user subject to potential electrical hazards. Making and breaking connections with them is an NFPA 70E “Normal Operation” and requires no PPE or special precautions.

In addition to eliminating the potential hazards common with pin and sleeve and other types of plugs and receptacles, MELTRIC Switch-Rated plugs and receptacles simplify NFPA 70E compliance by making it easy to establish an electrically safe working condition:

- They provide the safe and proper means of interrupting the load current.

- The removal of the plug from the receptacle provides clear visual verification of deenergization without the voltage testing required on bladed disconnects and rotary switches.

- Integral provisions make lockout/tagout simple on either the plug or the receptacle.

- Work can be done without the need for specially qualified personnel.

Lockout or Lock Together

All Switch-Rated devices include standard provisions on the plug that allow users to perform lockout/tagout by simply inserting a lock through an existing hole on the device. The user only needs to provide the lock – no additional mechanisms are required.

Simple lockout provisions for the receptacle are also provided as an option on the DS and DSN Series. A locking pin fits snugly in a circular opening through the pawl and prevents the pawl from operating. Various sizes of locks and lockout hasps can be used with the locking pin to complete the lockout.

The lockout provision on DS and DSN Series receptacles can also be used to lock the plug and receptacle together. This can be an important consideration in public or other critical areas where it is important to prevent unauthorized disconnections.

MELTRIC devices are compatible with lockout/tagout (LOTO) procedures, ensuring that workers can safely isolate equipment from power sources before performing maintenance, further enhancing electrical safety.

Incorporating MELTRIC's innovative technology into your electrical systems is a proactive step towards enhancing workplace safety and minimizing the risk of arc-flash incidents. By providing a secure, enclosed, and user-friendly connection system, MELTRIC devices contribute to creating a safer working environment for everyone involved.

Lid Options

Order the Best Plug/Receptacle Options for Washdown Performance. Choose from:

Normally Open (NO): If an operator is more than 20 feet from the device, as in cord drop applications, the standard NO lid is recommended because, at a distance, it is easily seen and readily indicates that the receptacle lid needs to be manually closed before washdown operations to keep internal components dry.

Normally Closed (NC): The NC lid requires an operator to manually close it to obtain a complete watertight seal. It is recommended that this option should be used when an operator is less than 20 feet from the device or within easy reach. This ensures the operator can see that the NC lid needs to be manually closed before washdown operations to keep the receptacle dry.

Enclosed Design

MELTRIC's Switch-Rated devices, designed with an enclosed construction, isolate live electrical parts, significantly reducing the risk of accidental contact during plug connections.

Mating-Specific and Self-Sealing Technology

MELTRIC devices feature a mating-specific and self-sealing design, preventing arc-flash incidents during the connection or disconnection process.

Simplified Maintenance

MELTRIC devices, designed to be user-friendly, facilitate safer and more efficient maintenance procedures. Reduced exposure to live electrical parts during maintenance lowers the risk of arc flashes.