VISIT US at a Trade Event

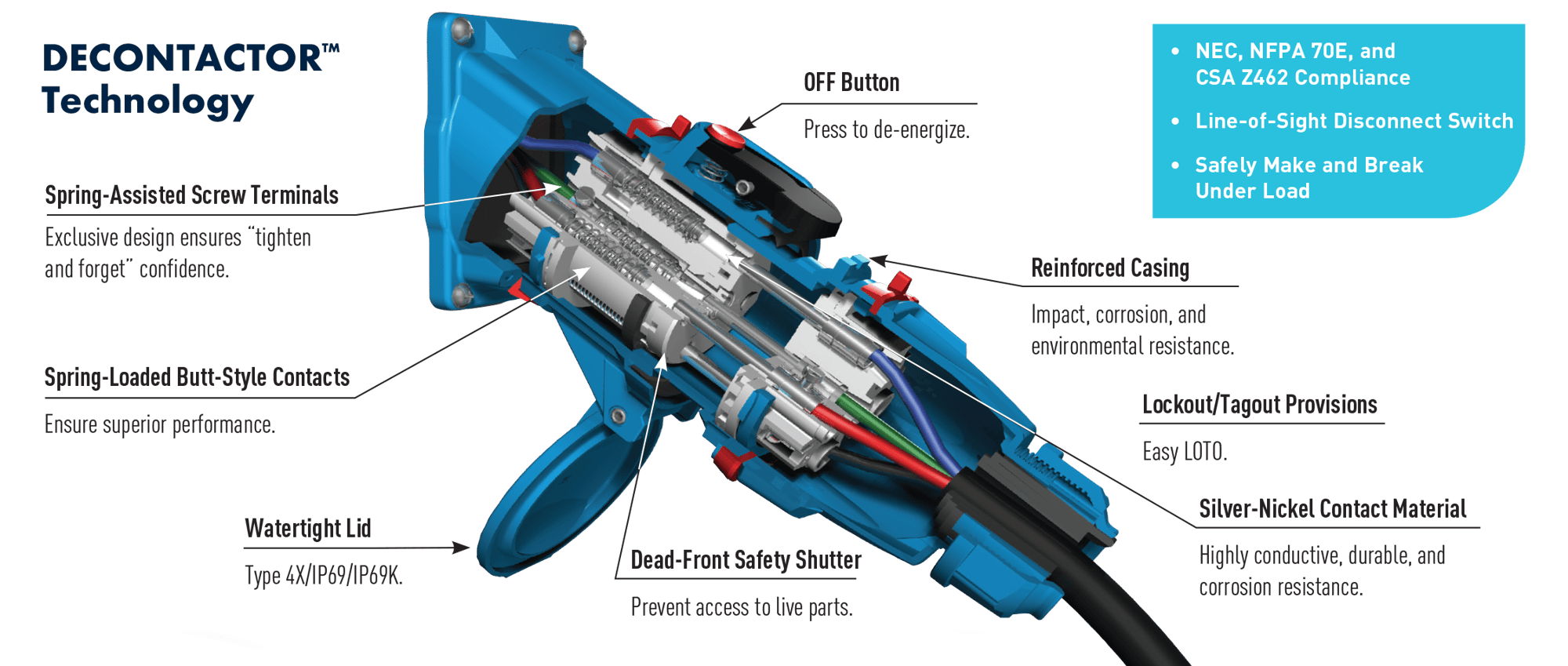

MELTRIC representatives will show you how you can optimize power connection safety in your facility. MELTRIC Switch-Rated Plugs and receptacles combine a dead-front safety shutter and an arc-flash chamber. Most MELTRIC devices are UL/CSA rated, meet NEC code requirements, simplify NFPA 70E code compliance, include LOTO provisions, and water resistance ratings.

MELTRIC's Main Focus is Ensuring Safety

Power with Confidence

MELTRIC® devices are equipped with state-of-the-art DECONTACTOR™ technology that actively eliminates the risk of arc flashes. Say goodbye to complex processes, cumbersome PPE, all while protecting your team and equipment.

Try a Device, On Us

Try a Free Electrical Plug and Receptacle, from MELTRIC,

MELTRIC SWITCH-RATED PLUGS AND RECEPTACLES...

provide the safety of a switch with every plug and receptacle. They allow users to safely make and break connections under full load and provide significant protection in overload and short circuit conditions. They are UL and CSA rated. MELTRIC’s Switch-Rated plugs and receptacles provide the safety and security of true dead-front construction.

Powering Progress, Protecting Lives

Prioritizing a safe workplace by eliminating arc-flash hazards is of utmost importance, and the perils of neglecting them can be devastating. Arc flash incidents are one of the top three serious electrical hazards and can cost a business more than $1 million per accident. On average, OSHA issues 40,000 safety citations per year.

MELTRIC devices eliminate risks associated with arc-flash and arc-blast, saving users from severe injury, hospitalization, or worse, death.

The MELTRIC Advantage

The MELTRIC® Advantage means exclusive Switch-Rated safety that you can rely on and trust. MELTRIC Switch-Rated Plugs and receptacles combine two distinct safety elements in one design. A dead-front safety shutter isolates all live parts, removing the risk of electrical shock to operators. Additionally, an arc-flash chamber safeguards users, allowing them to safely disconnect, even when under load. MELTRIC design helps ensure worker safety while reducing equipment and labor costs.

Most MELTRIC products are UL/CSA rated for motor circuit disconnect switching, and meet NEC code requirements for line-of-sight disconnects. Our devices also include lockout/tagout (LOTO) provisions, are watertight, and simplify NFPA 70E normal operation code compliance. Switch-Rated plugs and receptacles eliminate the need for expensive auxiliary disconnects and enable plug and play equipment changeouts.

Arc Flash Safety Chamber Design

- MELTRIC's devices, engineered with arc-flash chamber and resistant materials, withstand and redirect the forces generated from an arc flash, helping to minimize damage and protect personnel.

Enclosed Design

MELTRIC's Switch-Rated devices, designed with an enclosed construction, isolate live electrical parts, significantly reducing the risk of accidental contact during plug connections.

Mating-Specific and Self-Sealing Technology

MELTRIC devices feature a mating-specific and self-sealing design, preventing arc-flash incidents during the connection or disconnection process.

Simplified Maintenance

MELTRIC devices, designed to be user-friendly, facilitate safer and more efficient maintenance procedures. Reduced exposure to live electrical parts during maintenance lowers the risk of arc flashes.

Lockout/Tagout Compatibility

MELTRIC devices are compatible with lockout/tagout (LOTO) procedures, ensuring that workers can safely isolate equipment from power sources before performing maintenance, further enhancing electrical safety.

Incorporating MELTRIC's innovative technology into your electrical systems is a proactive step towards enhancing workplace safety and minimizing the risk of arc-flash incidents. By providing a secure, enclosed, and user-friendly connection system, MELTRIC devices contribute to creating a safer working environment for everyone involved.

MELTRIC Simplifies NFPA 70E Compliance

MELTRIC Switch-Rated plugs and receptacles simplify compliance with NFPA 70E by eliminating exposure to live parts and arcing when making and breaking electrical connections to changeout or service motors and other equipment. The hazard is eliminated, so there is no need for cumbersome PPE or time-consuming safety procedures.

MELTRIC Switch-Rated plugs and receptacles are designed specifically to ensure safe use and are UL/CSA rated for branch circuit and motor circuit disconnect switching.

-

They have a quick break mechanism that automatically ejects the plug to the ‘Off’ position and minimizes associated arcing.

-

Arcing that does occur is safely contained and isolated in internal arc chambers.

-

The design of the casings prevents access to live parts when the plug is ejected to the ‘Off’ position; this dead-front is maintained by a safety shutter which closes automatically over the receptacle contacts before the plug can be removed.

At no time in the process is the user subject to potential electrical hazards. Making and breaking connections with them is an NFPA 70E “Normal Operation” and requires no PPE or special precautions.

In addition to eliminating the potential hazards common with pin and sleeve and other types of plugs and receptacles, MELTRIC Switch-Rated plugs and receptacles simplify NFPA 70E compliance by making it easy to establish an electrically safe working condition:

- They provide the safe and proper means of interrupting the load current.

- The removal of the plug from the receptacle provides clear visual verification of deenergization without the voltage testing required on bladed disconnects and rotary switches.

- Integral provisions make lockout/tagout simple on either the plug or the receptacle.

- Work can be done without the need for specially qualified personnel.